Open Cell Foams

In stock materials ready to custom cut to any shape or size with or without adhesive.

Common Open Cell Foam Applications

| •

Air Filters

• Automotive Interiors • Automotive Packaging • BSR (Buzz, Squeak, Rattle) • Carpet Underlayment |

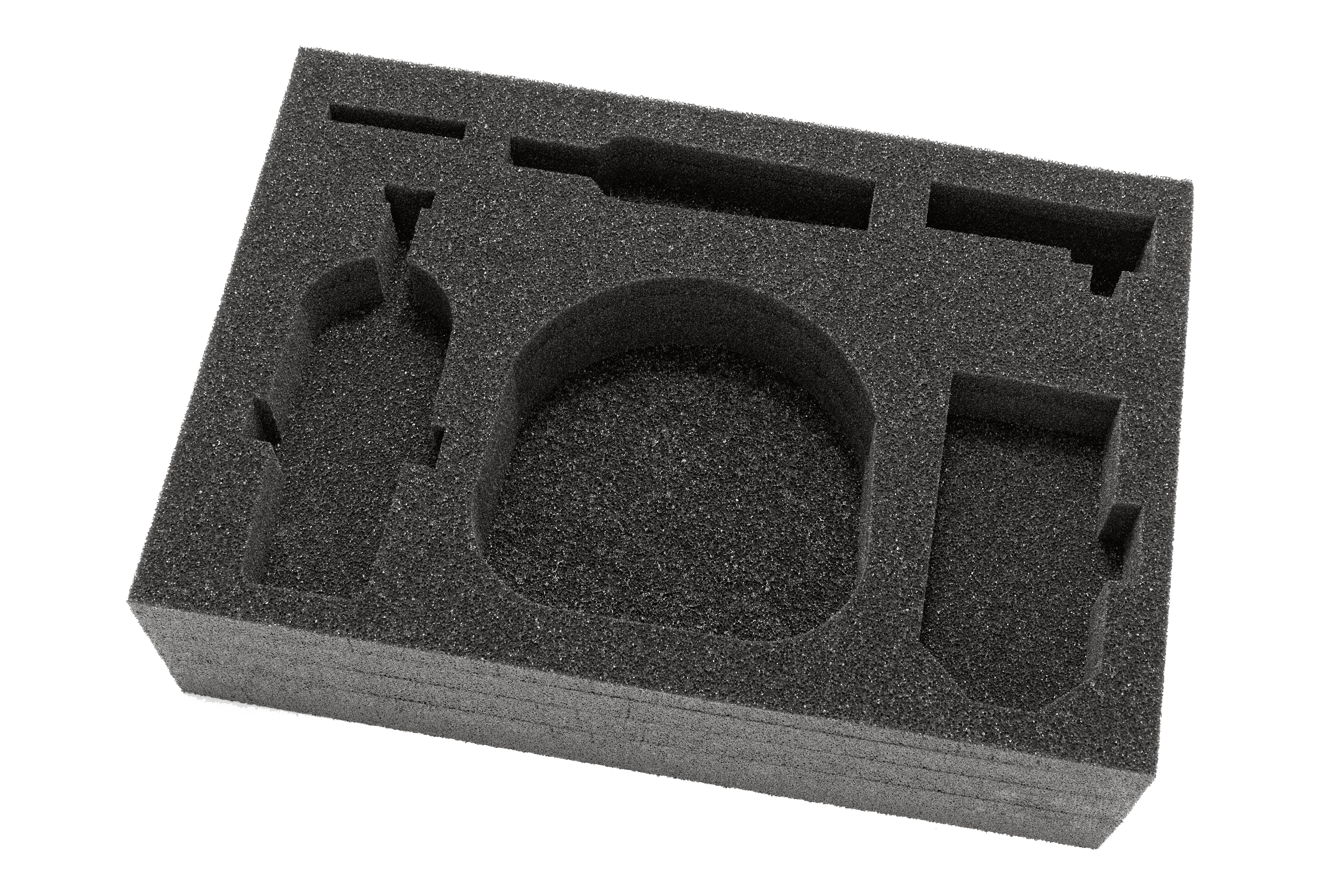

• Electronic

Packaging

• Filtration • Furniture Cushions • Mattresses/Pillows • Case Foam Inserts |

• Medical

Cushions & Equipment

• Promotional Items • Seals & Gaskets • Sound Absorbers (NVH) • Display Packaging |

Polyether

Polyether foam is a flexible, open-cell type of PU foam that has a near-infinite amount of applications due to its phenomenal characteristics.

• Lower Temperature Flexibility.

• Higher Resistance to Fungi.

• Better Hydrolytic Stability,

• Better Cushioning Capabilities.

• Superior Resistance to Moisture.

Polyester

Polyester foam is an effective, low-voltage insulating material used to create custom insulation for electronics & more. Easy to print on and easily bonds with most adhesives.

• Greater Abrasion Resistance.

• Higher Tensile Strength.

• Better Tear Resistance.

• Withstand Higher Temperature Longer.

• Improved Chemical Resistance.