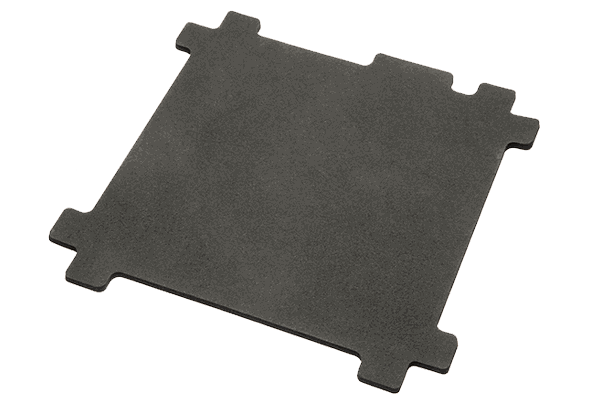

Neoprene Closed Cell Foam

High quality engineered foams to ensure your products are meeting performance and regulatory compliance standards.

Neoprene closed cell foam is UV, Ozone, and Weathering resistant. neoprene foams can be supplied with or without pressure sensitive adhesives on one or both sides.

2001 Neoprene Foam

• Black, Closed Cell Foam. 7-11 ft/lb3 density.

• ASTM D 1056 2A1/2C1 Requirements

• Excellent Ozone and UV Resistance

• Meets horizontal burn/flame requirements FMVSS 302 @ 3.1mm (1/8") and higher.

2002 Neoprene Foam

• Black, Closed Cell Foam. 7-11 ft/lb3 density.

• ASTM D 1056 2A2/2C2 Requirements

• Excellent Ozone and UV Resistance

• Meets horizontal burn/flame requirements FMVSS 302 @ 3.1mm (1/8") and higher.

2003 Neoprene Foam

• Black, Closed Cell Foam. 12-20 ft/lb3 density.

• ASTM D 1056 2A2/2C2 Requirements

• Excellent Ozone and UV Resistance

• Meets horizontal burn/flame requirements FMVSS 302 @ 6.35mm (1/4") and higher.

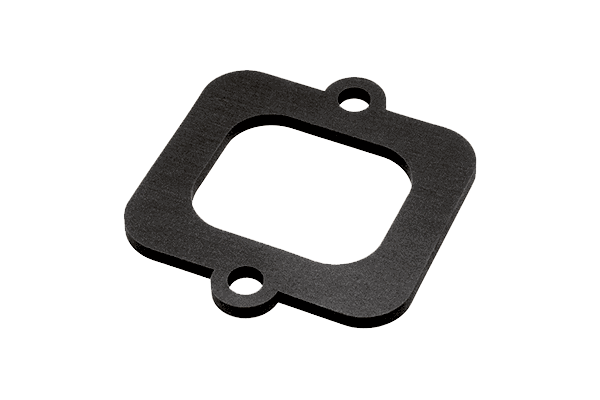

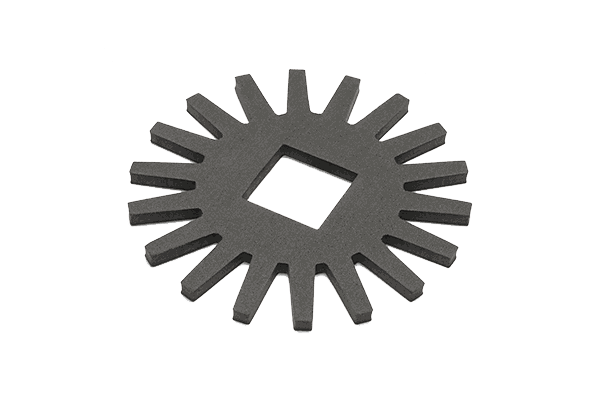

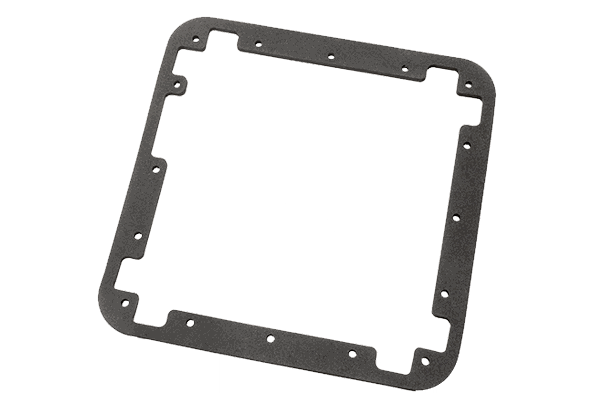

Neoprene Foam Applications

• Seals Gaskets

•Foam Strips Tapes

•Automotive Seals

• Construction Seals Insulators

•Electrical

Insulation

Start right now. Upload your CAD file to receive an Instant Quote.