Adhesives

Superior Technology, Superior Process.

Our digital system

automatically chooses the correct adhesive based on the substrate your part will

be adhering to. We offer a variety of adhesives to meet your performance

standards.

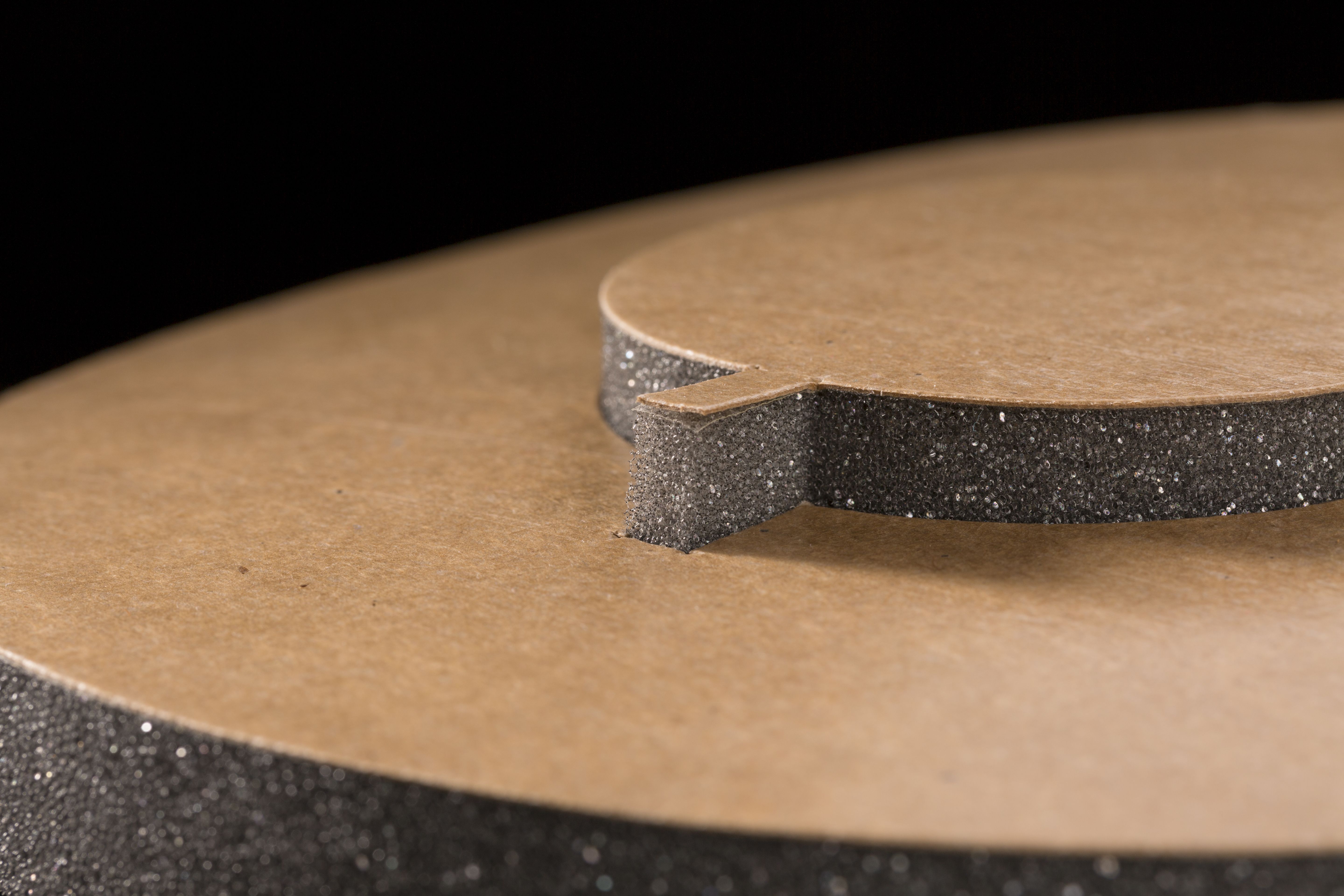

3M Adhesive Tapes

Acrylic adhesives open the door to solving the challenges of speed,

strength and

product shelf life. Attach. Seal. Reduce noise. Expand your materials — and your

design possibilities. Advanced adhesives keep it together under the harshest of

conditions, while you feel the thrill of defying creative limitations. Choose from

Transfer Tapes, Double Sided Tapes, Double Coated Foam Tapes, and Release Liners.

3M VHB Tapes

With 3M™ VHB™ Tapes, you can maintain consistency from sketch to

construction,

eliminating distracting, visible fasteners, like screws and bolts. These

high-strength, double-sided acrylic foam tapes let you quickly and easily create a

long-lasting bond that actually builds strength over time.

3M Foam Lamination Tapes

The perfect seal. Just the right amount of acoustic insulation.

Ideal impact damping.

Whatever your design challenge, there’s a 3M™ Foam Lamination Tape that can make

your vision a reality. Our L1/L2/L3 series adhesive platforms allow you to pair your

design with the right foam and adhesive for your application.

Don't see what you're looking for? Contact us to speak with one of our Sales Engineers to find the perfect adhesive for your product.

We can apply adhesives (acrylic/rubber) to all materials and supply your

parts on rolls, sheets, or individually. As well as, packaging parts in

cartons or bags.

Common materials that can be laminated with PSA (pressure sensitive adhesive)

• ABS (Acrylonitrile Butadiene Styrene)

• EPP (Expanded Polypropylene)

• EVA (Ethylene Vinyl Acetate)

• HDPE (High Density Polyethylene)

• LDPE (Low Density Polyethylene)

• PDS (Painted Surfaces)

• PE (Polyethylene)

• PET (Polyester)

• PP (Polypropylene)

• PS (Polystyrene)

• PUR (Polyurethane)

• PVC (Polyvinyl Chloride)

• SS ( Stainless Steel)

• FRBD (Fiberboard)

• TFPP (Talc Filled Polypropylene)

• TPE (Thermoplastic Elastomer)

• TPO (Thermoplastic Polyolefin)

• TPR (Thermoplastic Rubber)

Benefits of PSA's

• High tack acrylic and rubber based adhesives.

• Excellent foam bonding characteristics.

• Exceptional adhesion to a variety of substrates.

The primary success of bonding a pressure sensitive adhesive is not chemical or mechanical, but surface compatibility is the key element. Choosing the right adhesive is critical when dealing with low and high surface energy materials.

Upload your CAD file to receive an Instant Quote.