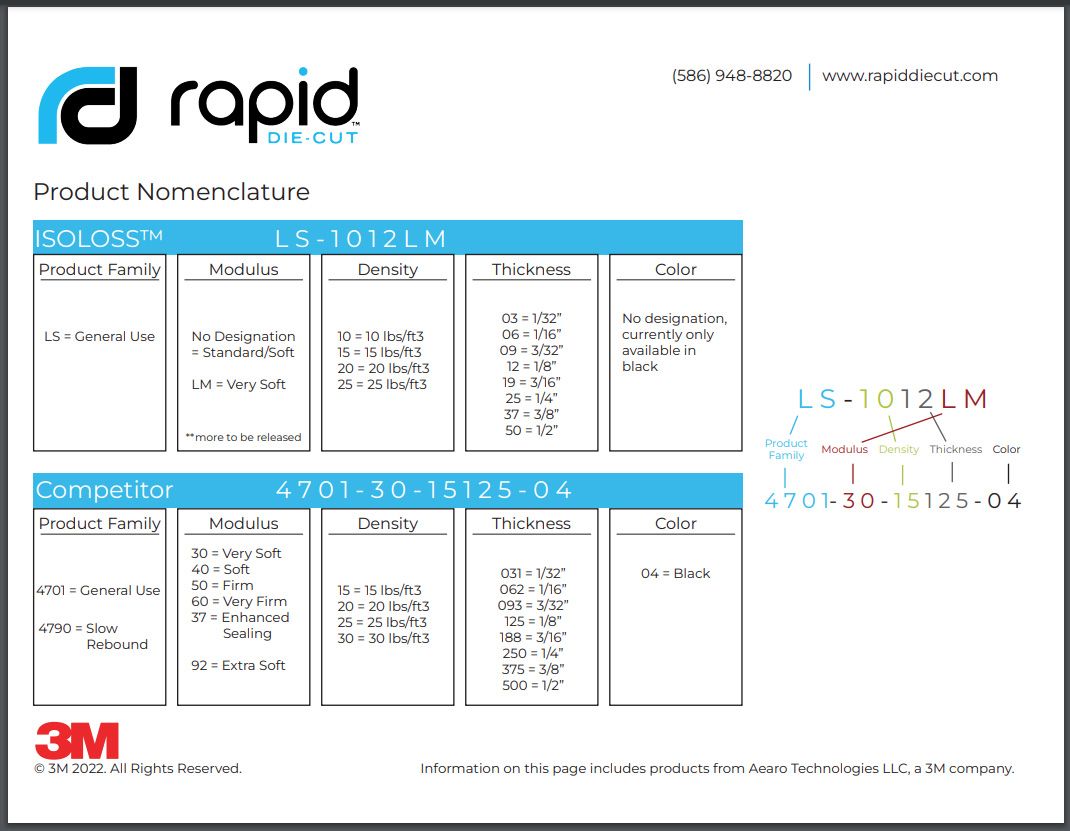

ISOLOSS™ LS Polyurethane

(Poron Equivalent)

What is LS Polyurethane Foam Used For

LS Foams are low compression set, high density urethane foams for gasketing, sealing and damping applications, and include a variety of thicknesses and densities to meet most application requirements.

Low Compression Set

The foam rebounds to maintain the same fit, form, and function throughout the

product's lifecycle.

Durable

Highly shock absorbent, and flame and chemical resistant foams provide strength and

longevity in extreme environments and temperatures.

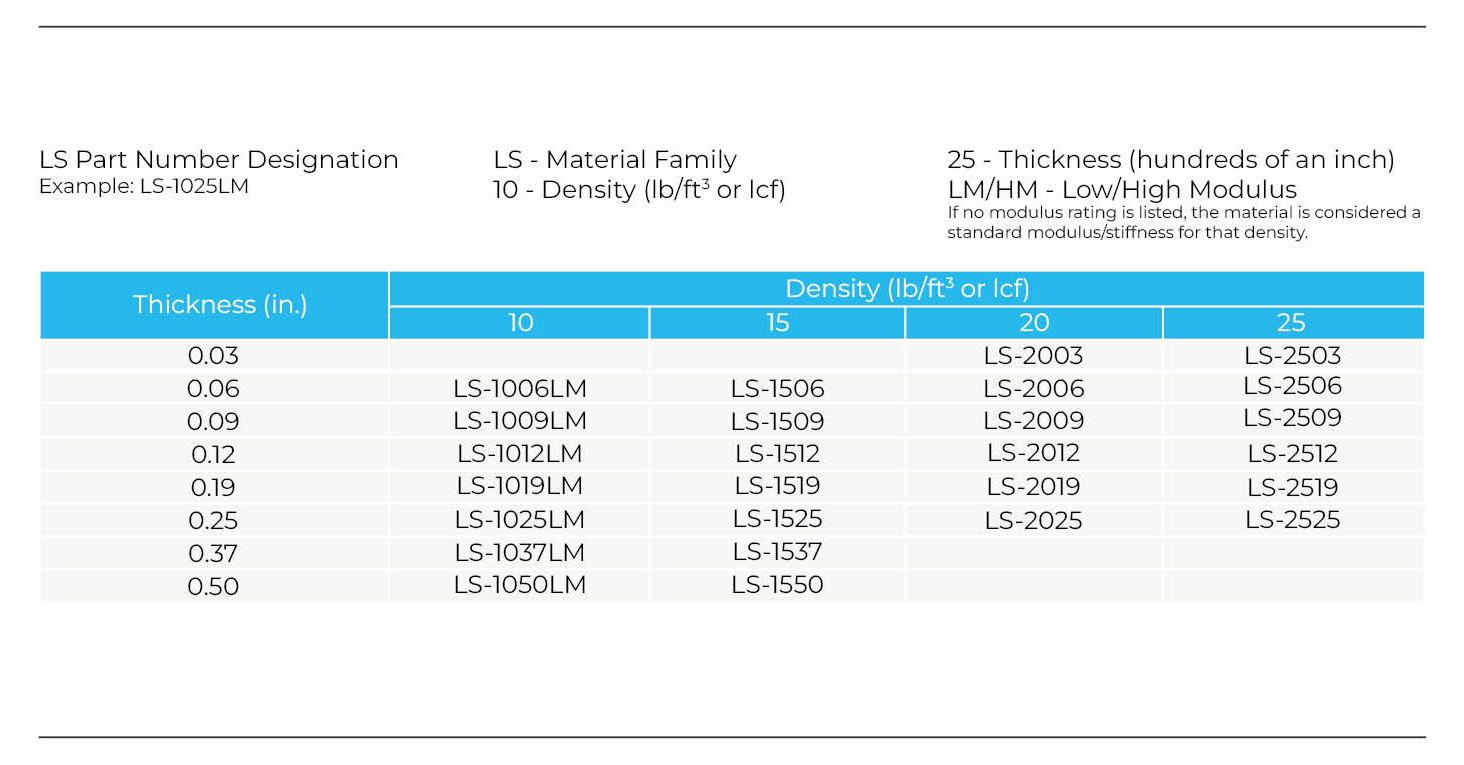

Variety of Densities & Thicknesses

A unique combination of design features allow for custom made solutions for different

applications.

Energy Control

From sensitive electronics to earth shaking heavy equipment, protect critical equipment from impact, shock, and vibration.

Gasketing & Sealing

UL gasket & sealing rated and pairs well with 3M™ Laminating Adhesives.

Cushioning & Support

Soft and supportive foam that conforms to the design and fills gaps to protect

equipment.

Common Applications Include:

• Gasketing

• Light duty sealing

• Enclosure seals

• Gap filling

• Vibration damping

• Shock absorbing

• Impact absorption

• Padding

• Buzz, Squeak, and Rattle (BSR)

• Noise, Vibration, and Harshness (NVH)

• Equipment & component mounts

Downloads